Modern manufacturing demands accuracy, speed, and reliability to stay competitive in global markets. A Metal Laser Cutting Machine has become an essential solution for industries that work with complex metal components and high-volume production. This advanced technology allows manufacturers to achieve clean cuts, tight tolerances, and consistent quality across different metal types. Laser Machine Manufacturers continuously refine these systems to meet the evolving needs of industrial production.

As industries move toward automation and smart factories, laser cutting technology plays a crucial role in improving productivity and reducing material waste. Businesses that adopt laser-based solutions often experience better efficiency and improved product quality.

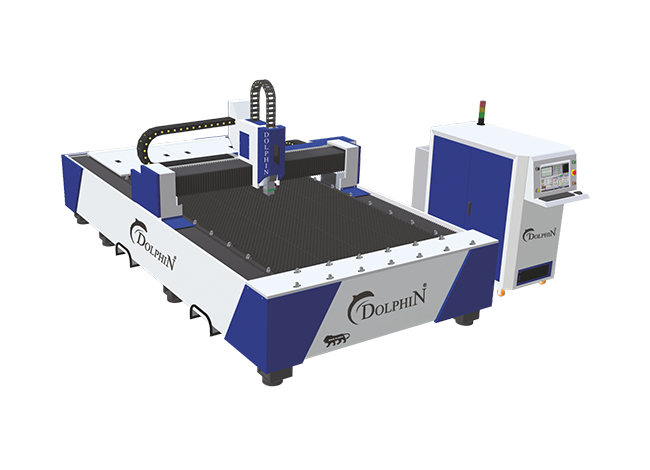

Metal Laser Cutting Machine and Core Working Principles

Understanding how laser cutting works helps industries appreciate its value. In a Metal Laser Cutting Machine, a concentrated laser beam melts or vaporizes metal at the cutting point, producing precise and smooth edges. The focused energy ensures minimal heat-affected zones, which protects the structural integrity of the material. Laser Machine Manufacturers design these machines to work effectively on steel, stainless steel, aluminum, brass, and other alloys. This versatility makes laser cutting suitable for a wide range of industrial applications, from simple components to complex geometries.

Metal Laser Cutting Machine Enhancing Production Speed

Speed is a major advantage in modern manufacturing, and laser cutting delivers impressive performance. A Metal Laser Cutting Machine operates at high speeds without compromising accuracy, allowing manufacturers to complete large orders within tight deadlines. Faster processing directly translates into higher output and improved operational efficiency.

Laser Machine Manufacturers integrate advanced motion systems and intelligent controls to optimize cutting paths. These features reduce idle time and ensure smooth transitions between cuts, resulting in consistent and repeatable production cycles.

Metal Laser Cutting Machine Supporting Industrial Versatility

Industrial environments require flexible solutions that adapt to different project requirements. A Metal Laser Cutting Machine supports a wide range of thicknesses and shapes, making it ideal for diverse industries such as automotive, construction, aerospace, and heavy engineering. Complex designs that are difficult to achieve with traditional tools become simple with laser technology.

Laser Machine Manufacturers offer customizable configurations to match specific production needs. This flexibility allows businesses to handle both small batch jobs and large-scale manufacturing with the same level of precision.

Metal Laser Cutting Machine Improving Cost Efficiency

Cost control remains a priority for manufacturers aiming to maximize profitability. A Metal Laser Cutting Machine helps reduce overall production costs by minimizing material waste and lowering energy consumption. Precise cutting ensures optimal use of raw materials, which reduces scrap and rework.

Laser Machine Manufacturers focus on energy-efficient designs that convert more power into usable cutting energy. Reduced maintenance requirements and longer service life further contribute to lower operating expenses over time.

Metal Laser Cutting Machine Delivering Superior Cut Quality

Product quality directly impacts customer satisfaction and brand reputation. A Metal Laser Cutting Machine delivers superior edge quality with minimal burrs and distortion. Smooth finishes often eliminate the need for secondary processing, saving time and labor costs.

Laser Machine Manufacturers incorporate advanced control software that maintains consistent beam focus and power output. These systems ensure uniform results across different materials and thicknesses, even during extended production runs.

Metal Laser Cutting Machine and Automation Integration

Automation has become a defining feature of modern manufacturing facilities. A Metal Laser Cutting Machine integrates seamlessly with CNC systems, robotic arms, and automated material handling solutions. This integration reduces manual intervention and improves workflow efficiency.

Laser Machine Manufacturers design machines that support automated loading and unloading, which increases safety and productivity. Automated systems also help maintain consistent quality by reducing human error during repetitive tasks.

Metal Laser Cutting Machine Promoting Workplace Safety

Safety is a critical concern when operating high-power industrial equipment. A Metal Laser Cutting Machine includes protective enclosures, safety interlocks, and emergency stop mechanisms that safeguard operators. These features help create a controlled and secure working environment.

Laser Machine Manufacturers comply with international safety standards and continuously improve machine design to reduce risks. Clear interfaces and operator training support safe and efficient machine operation on the shop floor.

Metal Laser Cutting Machine Supporting Sustainable Manufacturing

Sustainability is increasingly important in industrial decision-making. A Metal Laser Cutting Machine supports eco-friendly manufacturing by reducing energy usage and minimizing material waste. Efficient cutting processes result in fewer emissions and lower environmental impact.

Laser Machine Manufacturers invest in research to develop greener technologies that align with global sustainability goals. By adopting laser cutting solutions, industries can meet production demands while supporting responsible manufacturing practices.

Metal Laser Cutting Machine Driving Global Competitiveness

Global markets demand high-quality products delivered on time, and laser technology helps manufacturers meet these expectations. A Metal Laser Cutting Machine enables companies to produce complex components with consistent accuracy, enhancing their ability to compete internationally.

Laser Machine Manufacturers play a vital role in providing reliable systems that meet global quality standards. Advanced laser cutting capabilities allow businesses to expand into new markets and take on challenging projects with confidence.

Metal Laser Cutting Machine Shaping the Future of Industry

The future of manufacturing relies on precision, efficiency, and innovation. A Metal Laser Cutting Machine continues to shape this future by offering advanced features that support smart production environments. Continuous advancements in laser technology ensure improved performance and adaptability.

Laser Machine Manufacturers remain focused on delivering cutting-edge solutions that help industries grow and evolve. By investing in modern laser cutting systems, manufacturers position themselves for long-term success in an increasingly competitive industrial landscape